G. Electric power storage with an automated ski lift

G1. Predecessor inventions

The idea of pumping water uphill into ponds to store potential energy and letting it back down to generate rush-hour electricity is perhaps a century old. The costs of building ponds and some of the energy losses are significant, but hydropumping is now considered the electric grid's old standby for storing power.

One scheme used a cable to pull a fully loaded rail car up a mountain slope, and then it lowered the car to produce electricity. Yes, the scheme stored and produced a tiny amount of electricity, but the ratio of the electricity produced to the length of the cables and rails used was financially awful.

Energy Cache was conceived as a system that scooped up gravel and raised it up a hill using cars and cables. The economics weren't working. Energy Cache was abandoned in favor of another scheme, Energy Vault, where large concrete blocks were lifted vertically up a skyscraper-like crane device. These schemes both had a rather expensive ratio of steel cables needed to electric power delivered.

G2. Linked chains with smooth, precipitation-resistant tops

I'm equally going to incorporate these linked chains in my two kite electricity generation system and in my above-ground transit system.

Unlike twisted wire cables, motorcycle chains won't easily fray from constant bending and unbending. Also, sprocket teeth fit into roller chains for dependable power transmission.

Unlike twisted wire cables, motorcycle chains won't easily fray from constant bending and unbending. Also, sprocket teeth fit into roller chains for dependable power transmission.

It's possible to leave relatively long distances between chain links, assuming that all of the sprockets have been designed with teeth that match the roller chain's new link length. The purpose of leaving longer distances between chain links is to lighten the chain and to reduce the number of potential failure points on the chain. For extremely long chains of several kilometers in length, we might leave wide distances between links, say, 10 centimeters between links or even 1 meter between links. A single metal or carbon fiber rod might take up each gap of 10 centimeters to 1 meter, leaving room for a single gear tooth next to the end of each link in the roller chain. Matching sprocket gears would have 10 centimeter to 1 meter flat gaps between adjacent teeth.

I believe in building a flat roof section into each link in any outdoor linked chain that in use always has a weather side and a bottom side. A chain roof means that flying branches, flying pea stones, tree branches or other hard objects can't get jammed downward into the chain's links and then into the gears. Also, freezing rain stays on the chain's roof and soon cracks off, as opposed to precipitation freezing within the links. Sweeping brushes and de-icing salts might also help the chain with performance in winter weather.

In use a series of flat flanged wheels can roll across the top of the chain, keeping the chain aligned, while one or more large toothed wheels fully engage the chain from the bottom.

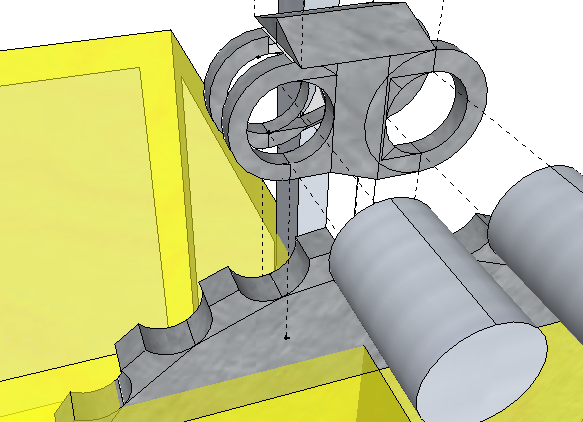

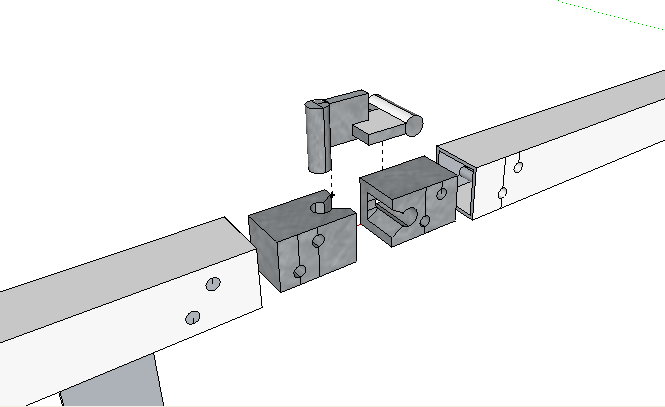

It's also possible to use square bars and few universal joint pivot points in chains, as long as toothed gears can grab certain holes in the evenly spaced bars. These square bars can inexpensively support a certain large amount of mass. Here's an exploded view of one of those joints. Once the joint is bolted into the two square pipes, the universal joint can't go anywhere. Oversized gear wheels have to fit these unique roller chains precisely.

It's also possible to use square bars and few universal joint pivot points in chains, as long as toothed gears can grab certain holes in the evenly spaced bars. These square bars can inexpensively support a certain large amount of mass. Here's an exploded view of one of those joints. Once the joint is bolted into the two square pipes, the universal joint can't go anywhere. Oversized gear wheels have to fit these unique roller chains precisely.

I'm about to employ similar roller chains in three different inventions: this energy storage ski lift, a kite system that generates wind electricity and an above-street transit system.

G3. A two-dimensional roller chain

For my energy ski lift I need a roller chain or possibly a cable that can be well-gripped by toothed gears for power transmission, and that can also bend sideways around wheels at the top and at the bottom of a ski lift.

In a two dimensional roller chain, every second link would be turned 90 degrees sideways. The chain can flex up-down as it goes around vertical sprockets and can flex left-right against other sprockets. Such a chain can be designed so that the teeth in vertical sprocket gears will fit into the bottom of the chain as the chain passes over these sprocket gears, and the teeth in horizontal sprocket gears will fit into at least one side of the chain as it passes next to these gears. I expect to find that a 2-dimensional linked chain or an equivalent solution has already been invented and used.

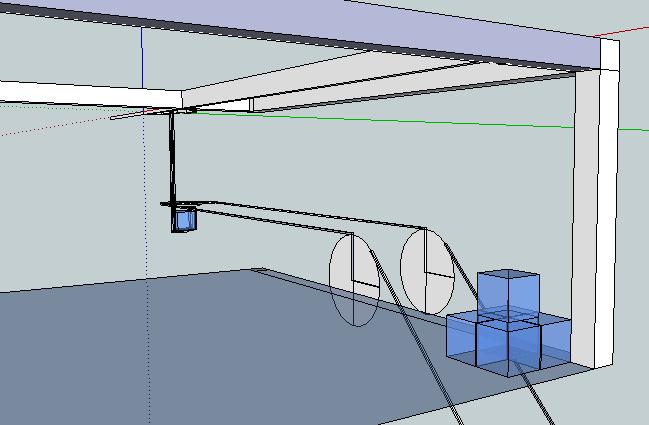

G4. A ski lift power transmission scheme

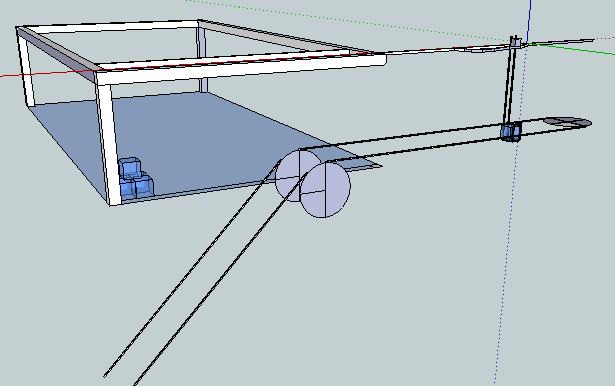

My ski lift carries mass up a mountain slope, stores the mass at the top of the mountain, then lets the mass back down the mountain slope, generating electricity. My prototype has an elevation change of 1000 meters, roughly the elevation from the top of Killington Peak in Vermont down an east-southeast slope to a nearby river valley 3,000 meters away.

My ski lift carries mass up a mountain slope, stores the mass at the top of the mountain, then lets the mass back down the mountain slope, generating electricity. My prototype has an elevation change of 1000 meters, roughly the elevation from the top of Killington Peak in Vermont down an east-southeast slope to a nearby river valley 3,000 meters away.

As is my inventor's habit, my ski lift happens to have exactly 100 power generating support towers, as good a number as any until site-specific information is needed. Each standard ski lift mass is one metric ton of rocks and other clean fill. The ski lift chain has connectors 30 meters apart, so that each stretch of roller chain between any two support towers is supporting 1 metric ton of mass. The ski lift chain moves at 3 meters per second.

During power generation mode, once every ten seconds a one ton mass is attached to the ski lift chain at the top of the mountain, and a one ton mass is detached at the bottom of the mountain every ten seconds. Every section of roller chain supports one metric ton of mass. A chain with a burst strength of 5 metric tons should properly support 1 ton weights suspended between adjacent support towers. The ski lift chain is empty as it loops back up to the top of the mountain.

During power generation mode, once every ten seconds a one ton mass is attached to the ski lift chain at the top of the mountain, and a one ton mass is detached at the bottom of the mountain every ten seconds. Every section of roller chain supports one metric ton of mass. A chain with a burst strength of 5 metric tons should properly support 1 ton weights suspended between adjacent support towers. The ski lift chain is empty as it loops back up to the top of the mountain.

In about 10 seconds each one ton weight drops 10 meters from one power generator wheel to the next wheel. This weight pulls on the roller chain, which pulls on the power generator's large sprocket wheel, which generates roughly 40 kilowatts for 10 seconds. Then another weight goes over the sprocket wheel and the generator continues to generate 40 kilowatts for another 10 seconds, and so on perpetually. All of the 100 generators run all of the time, so that the system generates 4 megawatts of dispatchable power. A system loaded with 125,000 tons of mass at its top can generate 4 megawatts times 72 hours of electricity.

During power storage mode, once every ten seconds a one ton mass is attached at the bottom of the ski lift. Each power station consumes 40 kilowatts plus a small energy storage penalty to lift that one ton mass, and every other one ton mass coming behind it, another 10 meters up the mountain.

During power storage mode, once every ten seconds a one ton mass is attached at the bottom of the ski lift. Each power station consumes 40 kilowatts plus a small energy storage penalty to lift that one ton mass, and every other one ton mass coming behind it, another 10 meters up the mountain.

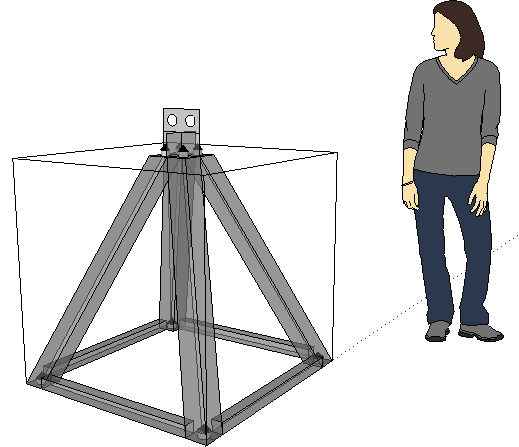

Each of the 100 support towers contains an electric dynamo. The dynamo translates electric power into turning the geared wheels so as to pull masses up the ski lift. It equally can translate the pull of masses traveling down the ski lift into electric power.

The beauty of having 100 energy generating support towers as opposed to building one large generator is that we store and retrieve an enormous total amount of electricity for every 30 meters of chain that we use and re-use all day and night.

This ski lift differs from the Energy Cache design in that each section of 100 feet of chain rated at a 5 ton breaking strength generates 40 kw of power over 10 seconds until it passes the first support tower, then again generates 40 kw of power over the next 10 seconds as it passes the second support tower, and so on for 1000 seconds over 100 towers, We realize a relatively high total generating capacity with a relatively chain breaking strength. We save money.

One adjustment: I don't want every dynamo to be heavily generating at exactly the same portion of each ten second interval. So, I want a 33 meter distance between weights so that on the energy generating downstroke, one weight is past its support tower's toothed gear and is pulling fully on that support tower's gear, while the next weight on the next support tower has yet to pass its support tower's gear.

G5. Sacks of mine tailings

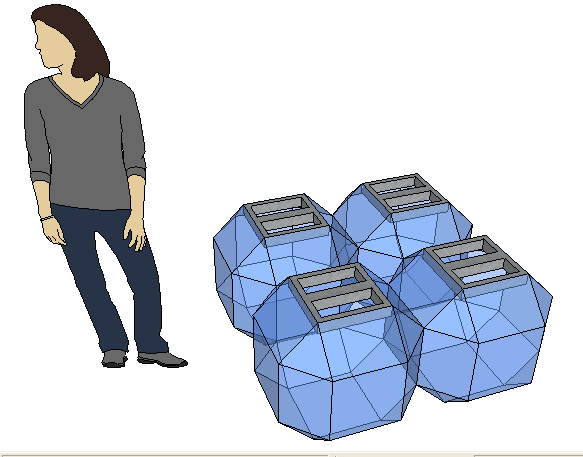

We can often use local mine tailings or any nearby rock or clean fill. A one ton bag of rocks might be held together with a type of stainless steel netting plus a dock for a hook at the top of each bag. I prefer a sack that can be stacked multiple layers high in warehouses at the ski lift's top and at its bottom.

We can often use local mine tailings or any nearby rock or clean fill. A one ton bag of rocks might be held together with a type of stainless steel netting plus a dock for a hook at the top of each bag. I prefer a sack that can be stacked multiple layers high in warehouses at the ski lift's top and at its bottom.

We need an automated system that removes each sack of rock from the ski lift chain, that energy-efficently transports sacks of rock to certain spots in the warehouse and stores them. We want to move the sacks of rock up or down as little as possible in order to save energy in the stacking process. The same automated system also picks up sacks of rock and attaches them to the ski lift. The chain’s deadweight hooks, the latch areas matching the ski lift's hooks, need to be confined firmly into place for a consistent transfer.

Any deadweight that fails an automated inspection can be flagged and put into a separate warehouse pile. A spare deadweight must be waiting for these occasional failures. We must expect such problems. If the system fails to latch a deadweight onto the ski lift chain, the ski lift system will simply generate 1% less power for the next 1000 seconds.

A walking crane can pick up or deposit the satchels at a warehouse. We may need multiple walking cranes to handle satchel pickup at a proper speed to match the ski lift.

A walking crane can pick up or deposit the satchels at a warehouse. We may need multiple walking cranes to handle satchel pickup at a proper speed to match the ski lift.

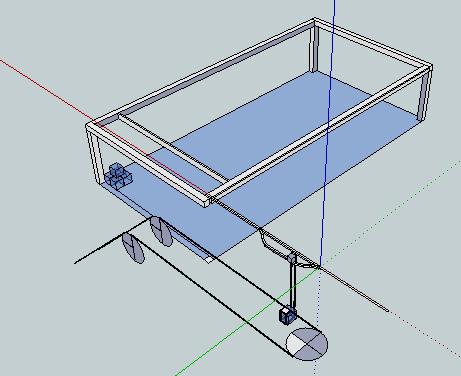

To the left is an internal ski lift weight frame. The frame allows ski lift weights to be stacked. Cne bottom corners of four adjacent weights will fit onto the top of the next weight below it. The sacks are tied to the top of the frame where lifting occurs. The 'floor" of the warehouse might be as simple as a square grid of supports with prongs that the weights fit on. The prongs point upward so that someday water doesn't accumulate in a downward-facing slot and freeze in it. The ultimate goal here is affordability per ton of stored weight, plus automated attachment of the weight to a slot on the ski lift.

G6. Safety

We want a one ton sack to not roll down a steep slope if it should ever fall off the ski lift. A deadweight with an elongated rectangular shape will be less able to roll down the mountain and cause trouble in case of an unexpected handling accident such as a metal stress failure. If the sack tears apart in its initial fall, most of the individual rocks won't roll that far.

G7. Impact

Renewable electricity is intermittent. To approach our nation’s commitment to achieve 100% renewable electricity, we need grid-scale storage.

Pumped storage is a currently used competitor. Certain hydroelectric dams can set aside some of their pondage as storage and can add extra turbines to their dams. When the local wind blows they let the local rivers fill up their pondage, and when the local wind doesn’t blow they let the excess water down to generate double their normal power. Unfortunately, large hydroelectric dams with room for pondage aren’t that common, and some older dams have been removed for environmental reasons. Pondage also leads to daytime evaporation losses. Construction of new dams and pumped storage facilities can contribute to greenhouse gas releases and local mercury releases into the water. Usable mountains with flat tops are uncommon. Our well-oiled gear system translating every foot-pound of motion into electricity can hopefully beat the 20%-30% round-trip energy loss that hydropumping storage now incurs.

Maintaining fossil fuel power plants on standby currently costs 16-22 cents per kilowatt-hour. As storable renewable power in all of its forms takes over 70% to 95% of grid electricity supply, the fixed costs of natural gas power plants, gas pipelines and gas wells will be amortized over fewer and fewer billing hours. Natural gas from the well also has an inelastic supply problem. The available gas gets quickly burned for heating or by cooling during peak winter and peak summer hours. Last and worst, fossil fuel plants have intractable greenhouse gas problems.

We want something affordable that works quickly and with few challenges. Wrapping tons of rock or of mining tailings in wires or in sacks with a standard hook on top makes the job of handling the rock much more reliable.

My real competitor is my own proposed geothermal heat storage system.

My ski lift usually won’t be high enough above the ground to generate a sunset flicker in a neighbor’s window. The deadweight system shouldn’t blow in a strong tornado, although the tornado could blow branches into the chain. A ski lift above ground level shouldn’t affect local wildlife or hikers. A ski lift will have a tiny ecological footprint going up a mountain and a small footprint at both of its ends. Finding a new use for local mine tailings might be considered a public service.

Assuming that we can achieve mass production of a $10 one-ton deadweight sack filled with local tailings or subsoil, where each deadweight is used an average of one round trip per six days, and we can build each tower/turbine for $50,000, we might achieve a total storage charge of $50 per megawatt-hour over 40 years. The favorable economics leaves us room for any unforeseen engineering errors, so that we have a high probability of success.

The technical risks of a purely mechanical system are low. Earthquakes and landslides are theoretical possibilities with vast weight movements, and we want to limit this risk.

This concept is mechanically buildable. It’s sustainable, it’s recyclable and it can be a good neighbor. HVDC lines can link wind fields and solar farms to mountain ranges. A gravity battery’s discharge time length can always be doubled by doubling the number of deadweights, and enough extra storage should put a goal of 99% renewable electricity within reach.

G8. Negawatt concepts

When electric demand stays greater than electric supply, expensive equipment fries out. We need to decide ahead of time who will defer their electricity usage during hours of peak electric demand. Our alternative is to defraud the usual victims.

A negawatt is for the most part a political invention. Negawatts certainly aren't my invention but we need to cover the waterfront.

G9. Preheating and cooling buildings

Heat and coolness are storable. We regularly warm all buildings to 68 degrees Fahrenheit around sunrise on January mornings, a peak winter demand hour. If we preheated the concrete parts and the innermost parts of buildings a few hours early then we could shave the winter morning peak.

A building with a heat pump can drive its basement floor heat storage into negative territory in order to shave the peak. If the center of the basement's concrete floor is way down to 50 degrees F and the second floor is at 67 degrees F, the building's heat pump can further lower the basement floor to 49 degrees F and apply that heat into the second floor. Eventually the winter sun will come out and the basement floor will once again be solar-warmed. This strategy works also with cooling buildings in July.

To integrate seasonal geothermal heating and cooling with our electrical grid's need to generate negawatts during periods of peak demand, we need to integrate a centralized weather forecasting function and electrical grid supply/demand to optimize electrical grid summer and winter performance in rare weather contingencies. To be effective we would need to monetize electrical peak load electricity savings. A market-based savings system integrates consumer and business preferences into these heating plans.

Many homeowners and landlords would prefer not to micro-manage their home's electrical network and their heating-cooling system. Personal micromanagement takes mental energy, brain power that most of us prefer not to spare. Optimally, people corruption-resistant and trustworthy outside micromanagement. We can be sure that people will never accept corrupt micromanagement on their own, and will veto or sometimes actively hinder all outside interference at the first sign of some of the corrupt government practices that now pervade our governments. The issue boils down to certain governments solving the corruption issues and winning, while other officials lie about their wanting to solve the corruption problem and then they seem to consistently fail. I focus on tiny-scale fair and democratic representation later in this book.

G10. Deferring electricity use

Electric vehicle owners will often get home at a peak summer demand hour in July. Some of the recharging could wait until the peak demand period is over.

G11. Optimizing the best times for electricity generation

Dams can store water. Manitoba Hydroelectric has signed a deal with Allete in Duluth, Minnesota to send 100 megawatts of hydropower down to Minnesota whenever the wind isn't blowing. When Allete's wind turbines are cranking, Allete sends 100 megawatts of power north to Manitoba and water builds up behind Manitoba Hydro's dams. I've also read about this type of power storage arrangement in Europe. Dam water levels on the Colorado River are so low these days that the dams have intermittent dispatchable power, not continuous dispatchable power at all.

Some solar power towers are storing heat, putting perhaps four hours of heat into storage for early evening generation. This storage more closely matches a hot region's peak summer power demand.

A geothermal steam plant holding marginal ground temperatures might only be run during peak winter demand hours.

Rivers run pretty low in summer during droughts, where droughts can be related to peak power demand. Upland swales turn surface runoff into groundwater, where such groundwater should stay in the ground for days or weeks before percolating its way into a stream. I expect that millions of microswales, easily built swales where each swale captures enough runoff to water one tree on a slope, will be extremely cost-efficient at storing local precipitation in the ground and at creating a steadier stream flow downstream in times of drought.

A mill pond can store and release a flow of water to power one or more “run of the river” hydroelectric projects downstream through a peak demand hour.

Wherever mountain glaciers have been restored, they melt on summer afternoons and shift stream flow to later in the season. See the mountainside chimney section for information on restoring mountain glaciers.”

G12. Stored electricity

All stored electricity schemes have a lifetime carbon cost for the storage unit's construction , and there's an energy penalty for each cycle of storing and releasing electricity. A storage plant usually has a limited storage capacity, although storage limits for seasonal storage can be enormous. Often there are time-dependent energy leakage costs.

I describe the race to cost-efficiently store electricity as a high stakes horse race. Some of the more well-known horses in this race would be hydropumping, batteries, hydrogen gas storage and compressed air storage in abandoned mines. Biofuels and fossil fuels can qualify as stored electricity, noting that fossil fuels have carbon dioxide and methane pollution issues.

G13. Sending people home

Schools and factories must live with snow days. We could design an electricity auction market so that individual factories could stay open whenever they're willing to pay exorbitant peak-load electricity costs for that day. Otherwise they could announce a brownout day for their most electricity-hungry industrial operations.

G14. Daylight Savings Time

Daylight savings time was adopted by many countries in World War I to displace fuel use. Daylight savings time enables all industries and businesses in a region of the world to start later in the winter and then start earlier in the summer, on a fixed schedule.

Certain higher latitude regions could save more energy with a total of 2 hours of shift forward. New York City, for example, has a sunrise of 7:17 a.m. Eastern Standard Time on December 21, and so in winter people pretty much get up with the sunrise and use all of their available daylight. However, NYC has a sunrise at 5:25 a.m. Eastern Daylight Savings Time on June 21. Even the earliest of NYC early birds who get to work by 7:00 a.m. in the summer have already wasted an hour and a half of daylight, never mind the business people who choose to arrive at 9:00 a.m. Also, NYC is naturally cooler on summer early mornings, so that NYC would burn less air conditioning electricity. People would feel better in the early morning when there's less smog.

It might be easier on our personal biological clocks if we all shifted our work schedules forward 1/2 hour per day within a two day period. Schools and companies might choose to pitch in here by delaying their opening by 1/2 hour for one Monday per year following the “spring.forward” time change.

I recognize that I have avoided discussing any government-designed negawatt implementation strategies. Sorry, but my overall faith in most governments' political integrity is limited. If the government is verifiably honest, as opposed to the government self-proclaiming its integrity without any activist community support, then an implementation strategy is possible.